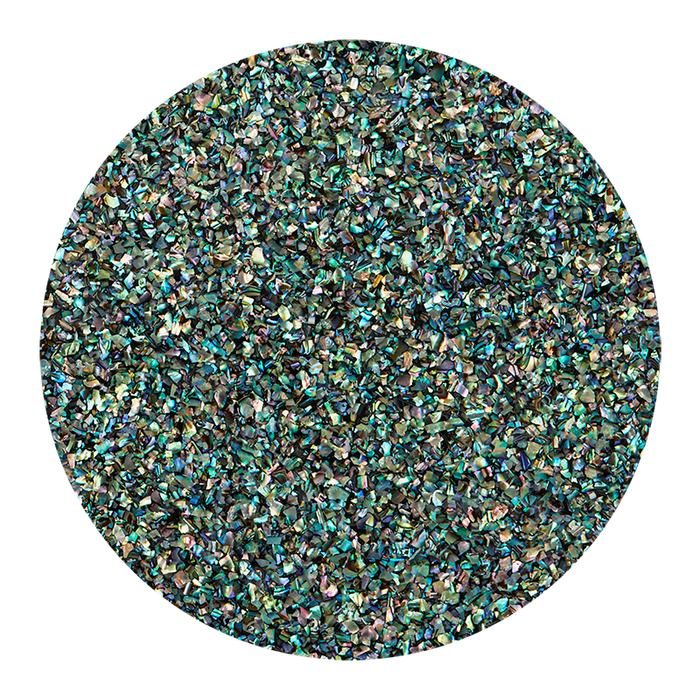

Genuine 100% natural shell veneer made with very fine pieces of New Zealand Abalone, called Paua. The most colourful abalone in the world, this veneer is a complex iridescent mix of blues, greens, purples and pinks with black veining accentuated by the black backing. Gloss finish and opaque backing. Light and versatile. Approx. .3 mm thick, these AAA quality sheets are perfect for inlays into wood, metal or acrylic, as well as fashion and accessories. Used by luxury brands world wide. Sustainability and provenance guaranteed. Can be cut with sharp scissors, a Kraft knife or laser cutter.

Abalone Paua Natural Galaxy Shell Veneer

Overview

Key Features

- Shell Type: New Zealand Abalone Paua (Haliotis Iris)

- Colour: Natural with Purple tint

- Finish: Gloss coated

- Quality: AAA

- Pattern: Random fine pieces

- Size: Useable area 200x200mm (actual size 205x205mm)

- Thickness: Approx. 0.3mm

- Backing: Black opaque acrylic